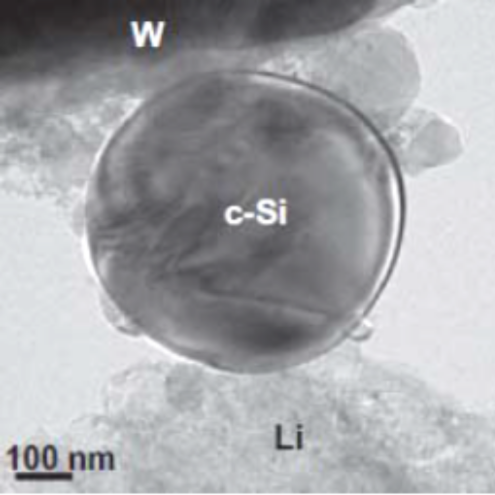

During charging-discharging phases in a lithium-ion battery, silicon inclusions undergo volume variations due to lithium ions. These variations in volume provoke large dimensional changes in particles that are therefore subject to high mechanical loads.

This issue is quite similar to what occurs during the irradiation of nuclear fuel, in particular heterogeneous MOX fuel, i.e. (U,Pu)O2. This fuel can undergo differential swelling, which generates mechanical stress that can result in the appearance of irreversible deformation.

For several years now, the Fuel Studies Department (DEC) has been developing digital tools to simulate the mechanical behaviour of materials with inclusion phases.

Applied to battery electrode materials, these tools have greatly advanced our understanding of the mechanical behaviour of a silicon particle during lithiation.

A semi-analytical elastic-plastic model has been developed and is used to reproduce the experimental observations.

The objective of these multi-scale simulation studies is to increase the capacity of the battery anodes to absorb lithium.